Index / Products

1059

De-Oxygenase Enzyme

Features and Benefits

- • Rapid removal of hydrogen peroxide

- • Significantly reduces treatment costs

- • A Wide range of applications:semiconductor, optoelectronics, pulp & paper, and textile dyeing industries.

- • Customizable formulations based on waste liquid characteristics.

- • No impact on discharge standards; no sludge generation.

- • No impact on the environment.

- • Resistant to interference from metal ions (e.g., Cu, Fe) which typically affect standard enzyme activity

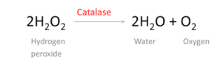

Reaction mechanism

Comparison of Commonly Methods for Hydrogen Peroxide Removal

| ADVANTAGES | DISADVANTAGES | |

|---|---|---|

| Activated Carbon | ㆍ Strong hydrogen peroxide removal capability ㆍ Capable of adsorbing organic compounds | ㆍ Fragile and prone to breakage, resulting in high consumption. ㆍ Treatment systems are prone to clogging |

| Ferrous Ion (Fenton Process) | Simultaneously removes COD | ㆍ Sludge disposal is required ㆍ pH adjustment ㆍ The concentration of hydrogen peroxide should not be too high before treatment. |

| Sodium Thiosulfate | No sludge generation | ㆍ High chemical dosing cost and large dosing volume ㆍ Prone to residual hydrogen peroxide. ㆍ Significant increase in conductivity |

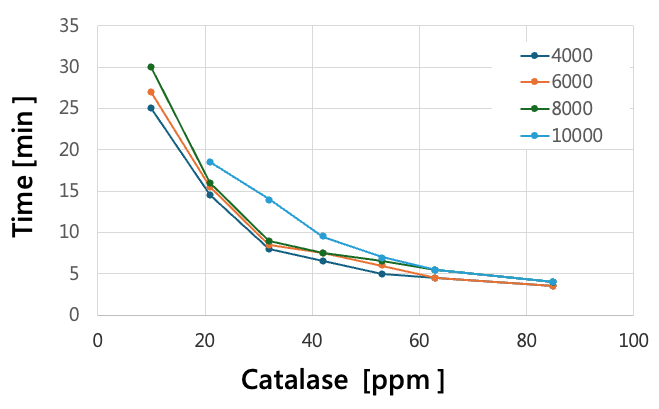

| De-Oxygenase Enzyme | ㆍ Low investment cost. ㆍ No need to change existing equipment. ㆍ Removes 90% of hydrogen peroxide in 10 minutes ㆍ No sludge generation ㆍ No impact on COD, ammonia nitrogen, or other parameter levels. ㆍ Capable of treating high-concentration hydrogen peroxide | ㆍ Dosing cost comparable to the Fenton Process ㆍPoor thermal stability; higher dosage required at temperatures above 45°C. |