1062

Customized Static-Dissipative DLC Coating

In response to the electrostatic damage risks caused by linewidth scaling below 20 nm in advanced semiconductor processes, Hans-tech, Trusval, and ITRI have formed a tripartite industry-academia collaboration. By integrating advanced PVD technology with an improved magnetic furnace arc ion system, we have jointly developed a surface-modified diamond-like carbon coating (ESD-DLC). This coating addresses the limitations of existing products, such as poor electrostatic dissipation, short lifespan, high costs, and dependence on external technologies.

Features

Stable electrical performance

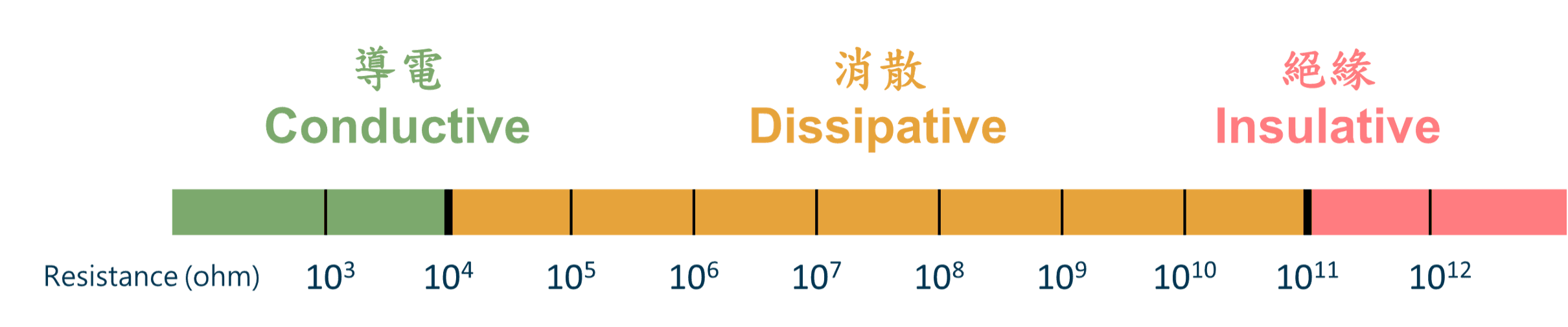

The DLC coating has a surface resistivity between 10^5 and 10^10 ohms/sq, complying with the ANSI/ESD S541 standard for electrostatic dissipative materials.

Applicable Metal Substrates

Primarily used on various metal carriers and workpiece surfaces, providing long-lasting and stable electrostatic dissipation.

Improves Limitations of Conventional Products

Coating Specifications

| Specification | Description | Features |

|---|---|---|

| Coating Color | Black, Dark Gray, Glossy / Matte | Surface Blackening |

| Technology | Cathodic Arc Deposition | Dense, 3D Coating, Low Contamination, Cost-effective |

| Structure | Multi-layer Design | Excellent Adhesion, With coating toughness |

| Thickness | 3-10 µm | No Impact on Original Dimensions |

| Surface Resistivity | 10^5-10^10 ohm | Stable quality, Customized service |

| Heat Resistance | Max. 250-300 ℃ | Applicable to high-temperature environments |

| Coating Hardness | 12-25 GPa | Wear-resistant, Prolongs service life |

| Applicable Objects | Substrates, fixtures, nozzles, suction heads, Clamps, robotic arms, gaskets, etc. | Suitable for stainless steel, carbon steel, aluminum alloy, and most conductive materials |

| Industry Applications | Semiconductor, IC packaging and testing, inspection and transfer equipment components, etc. | High ESD protection required; products or processes sensitive to ESD. |

Differences in Coating Properties

| FIELD1 | ESD-DLC PVD |

|---|---|

| Thickness | 3-10 µm |

| Density | Excellent |

| Adhesion | Excellent |

| Surface Resistivity | Tunable |

| Resistance Uniformity | Good |

| Coating Hardness (GPa) | 12-20 |

| Heat Resistance | > 250℃ |